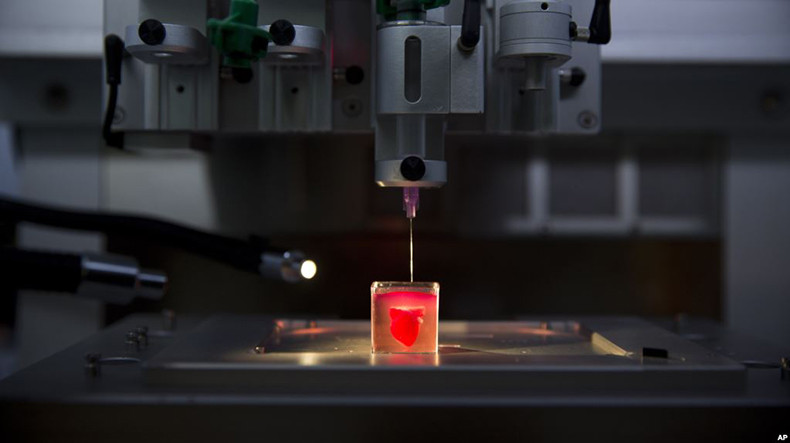

Israeli scientists 'print' world's first 3D heart with human tissue

A team of Israeli researchers has “printed” the world’s first 3-D vascularized, engineered heart, The Jerusalem Post reports.

On Monday, a team of Tel Aviv University researchers revealed the heart, which was made using a patient’s own cells and biological material. Until now, scientists have successfully printed only simple tissues without blood vessels.

"This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles and chambers,” said Prof. Tal Dvir of TAU’s School of Molecular Cell Biology and Biotechnology, Department of Materials Science and Engineering in the Center for Nanoscience and Nanotechnology, and the Sagol Center for Regenerative Biotechnology, who was the lead researcher for the study.

He worked with Prof. Assaf Shapira of TAU’s Faculty of Life Sciences, and Nadav Moor, a doctoral student. Their research was published in Advanced Science.

Heart disease is the leading cause of death among both men and women in the United States. In Israel, it is the second largest cause of death (after cancer). In 2013, heart disease accounted for about 16% of the total number of deaths in Israel, according to the Health Ministry.

Heart transplantation is often the only treatment available to patients with end-stage heart failure. The waiting list for patients in the US can be as much as six months or more. In Israel and the US, many patients die while on the waiting list, hoping for a chance at survival.

“This heart is made from human cells and patient-specific biological materials. In our process, these materials serve as the bio-inks, substances made of sugars and proteins that can be used for 3-D printing of complex tissue models,” Dvir explained.

“People have managed to 3D-print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future,” he said.

At this stage, the 3-D heart produced at TAU is sized for a rabbit, but the professors said that larger human hearts could be produced using the same technology.

For the research, a biopsy of fatty tissue was taken from patients, according to a release. The cellular and a-cellular materials of the tissue were then separated. The cells were reprogrammed to become pluripotent stem cells that could then be efficiently differentiated into cardiac or endothelial cells. The extracellular matrix (ECM), a three-dimensional network of extracellular macromolecules, such as collagen and glycoproteins, was processed into a personalized hydrogel that served as the printing “ink.” The differentiated cells were then mixed with the bio-inks and were used to 3D-print patient-specific, immune-compatible cardiac patches with blood vessels and, subsequently, an entire heart.

According to Dvir, the use of “native” patient-specific materials is crucial to successfully engineering tissues and organs.

The next step, they said, is to teach the hearts to behave like human hearts. First, they will transplant them into animals and eventually into humans. The hope is that within “10 years, there will be organ printers in the finest hospitals around the world, and these procedures will be conducted routinely,” Dvir said.

Newsfeed

Videos